China vs USA Mailer Box Prices: 2026 Comparison

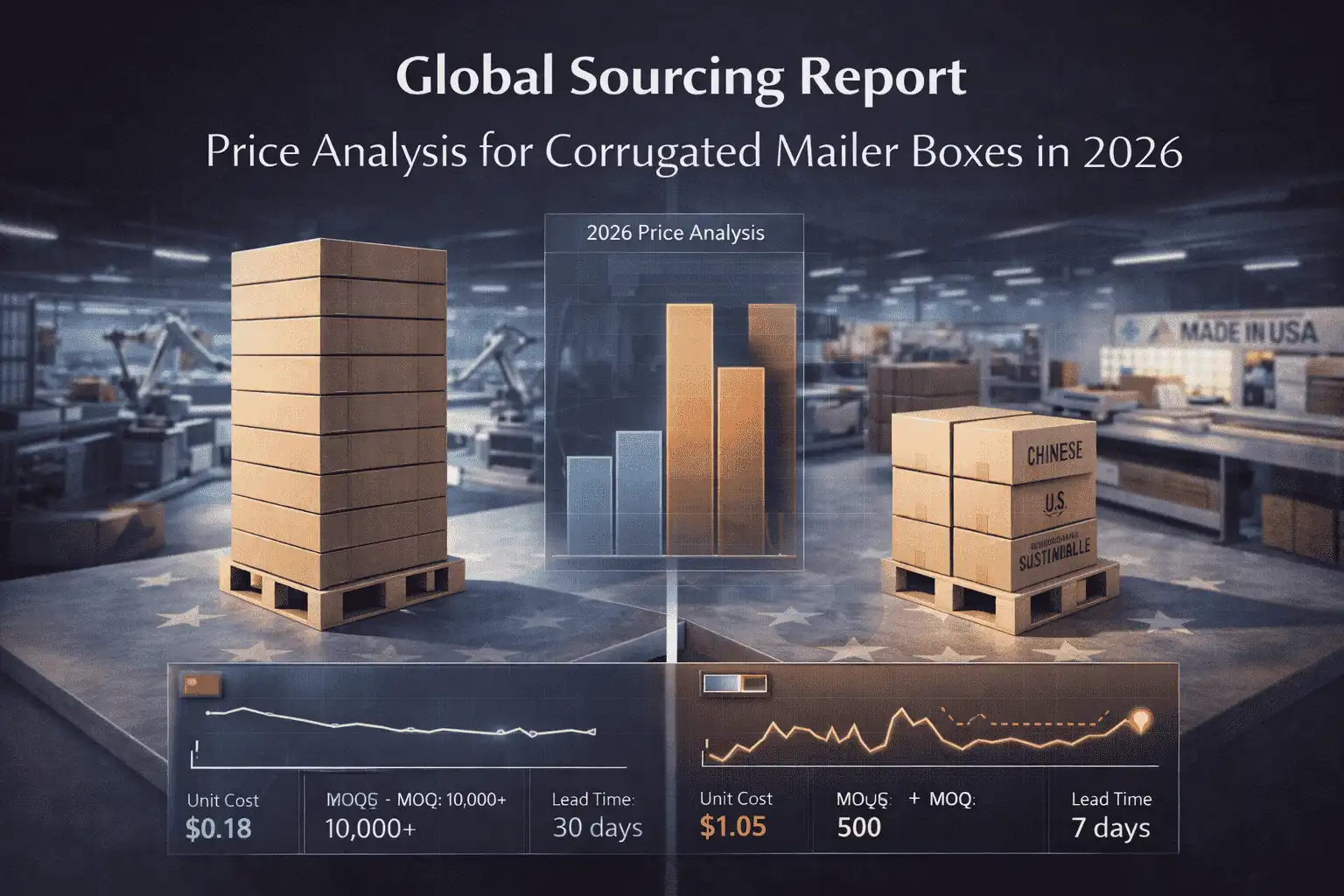

Due to different manufacturing capacities and market dynamics, the 2026 mailer box market shows notable price differences between Chinese and American producers. American manufacturers prioritize superior quality standards and quicker delivery options, while Chinese suppliers continue to use manufacturing scale advantages to provide competitive base price. Pricing structures in both areas are altered by rising raw material prices, changing sustainability standards, and changing logistical patterns. This creates difficult procurement decisions for companies looking for the best packaging options that strike a compromise between cost effectiveness and quality standards.

Market Overview of Mailer Boxes in China and USA

With different production capacities and supply chains, China and the USA are two of the world's most important mailer box manufacturing centers. The USA gains from cutting-edge technology, strict quality standards, and quicker turnaround times, while China leads with large-scale, economical manufacturing capacity backed by a strong network of suppliers.

China's Manufacturing Dominance

With Guangdong, Zhejiang, and Jiangsu producing the most, China's packaging sector has developed into a complex ecosystem that spans many provinces. Due to robust local demand and export potential, the nation's corrugated packaging industry produced significant income in 2025. Using automated manufacturing lines and economies of scale, Chinese manufacturers are excellent at creating bespoke colored mailer packing boxes at cheap prices.

China's packaging sector is supported by a network of integrated supply chains, specialized industrial parks, and cutting-edge printing technology. Multiple production processes are often housed under one roof in manufacturing facilities, allowing for a smooth workflow from design ideation to final package assembly. While preserving production flexibility, this vertical integration makes a substantial contribution to cost minimization.

USA's Quality-Focused Approach

In their mailer box manufacturing methods, American manufacturers place a high priority on precise engineering, environmentally friendly materials, and regulatory compliance. The domestic market places a strong emphasis on unique design skills that satisfy particular industrial needs, durability testing, and quality certifications. Premium corrugated mailer boxes with improved protection features for shipments of electronics, cosmetics, and luxury products are often the area of expertise for USA vendors.

Due to their close proximity to key transportation networks, regional industrial clusters in the Midwest and Southeast of the United States benefit from lower logistical costs for domestic distribution. American plants usually make significant investments in modern quality control systems, worker safety procedures, and environmental compliance to guarantee consistent product performance across production runs.

Market Dynamics Shaping 2026 Pricing

Increasing labor costs, raw material prices, and changing logistical issues all have a significant impact on price changes in 2026. The economics of production in both locations are directly impacted by the price of paper pulp, energy costs, and transportation charges. Furthermore, market dynamics are changing due to trends like personalization and sustainable packaging, which have a particular impact on price structures in both areas.

Environmental restrictions encourage the use of recycled and biodegradable materials, which are often more expensive than conventional materials. Eco-certified packaging solutions are becoming more and more in demand from consumer companies, forming market niches where sustainability credentials affect choices beyond just price.

Detailed Price Comparison: China vs USA Mailer Boxes

Different cost factors are revealed via a sophisticated pricing comparison based on order amounts, materials, and packaging choices. Beyond initial unit price, the research takes into account a number of variables that impact overall procurement costs.

Volume-Based Pricing Structures

Businesses exploring new product lines or seasonal promotions may afford Chinese manufacturers' appealing price tiers, which often start at lower minimum purchase quantities. When production efficiency optimize cost benefits, large colored mailer package boxes often attain optimum price at volumes surpassing 10,000 pieces. Chinese vendors can accept different order amounts without incurring major pricing penalties because to the flexibility of production scheduling.

Higher volume commitments from American suppliers show competitive positioning, with the benefits of local logistics offsetting higher production costs. Improved quality control procedures, quicker turnaround times, and extensive customer support are all reflected in premium pricing. Value-added services like design advice, prototyping, and logistics coordination are often included in stated rates for colored shipping boxes from US manufacturers.

Material and Customization Cost Factors

Eco-friendly materials are more expensive in both nations, and custom printed boxes are usually more expensive than conventional designs. Pricing for mailer boxes is greatly influenced by the choice of material, with kraft paper, corrugated cardboard, and specialized substrates all having different cost profiles. various areas have various effects on the overall project economics of advanced printing processes, such as offset printing for big volumes or digital printing for short runs.

Pricing structures are influenced by customization complexity; basic logo application is quite different from multi-color designs that need exact color matching. American manufacturers provide better assistance for intricate design specifications and quick prototype development, while Chinese suppliers often thrive in high-volume bespoke projects with competitive tooling prices.

Total Cost of Ownership Considerations

To properly maximize total cost of ownership, procurement managers must take into account freight costs in addition to dimension-specific and style-based price variations. Additional factors influencing buying choices include shipping costs, import tariffs, and delivery schedules. Comprehensive cost analysis is influenced by insurance needs, quality control procedures, and possible reshipping expenses.

In order to justify premium price for time-sensitive product launches, lead time concerns become crucial when assessing supplier possibilities. Beyond the initial purchase price, other factors that affect supplier selection include cash flow consequences, storage needs, and inventory holding expenses.

Quality and Durability Differences Affecting Cost Efficiency

When comparing package providers from China versus the USA, quality and durability are still important factors to take into account. Regional differences exist in the availability and pricing structure of materials, such as corrugated vs kraft paper and creative substitutes.

Material Standards and Testing Protocols

Stricter industry standards and testing procedures are often followed in the USA, guaranteeing reliable durability appropriate for valuable cargoes. Certifications for food-grade materials, pharmaceutical packaging conformity, and other industry needs are often maintained by American manufacturers. In order to verify package performance under shipping stress circumstances, rigorous testing techniques include assessments of compression resistance, edge crush strength, and burst strength.

Chinese producers have greatly improved their quality control procedures, putting international norms into practice and earning certificates that are on par with international standards. To guarantee product uniformity across manufacturing batches, modern Chinese facilities use advanced testing apparatus and quality management systems. Investing in high-quality infrastructure is a reflection of how the sector has changed to satisfy the demands of the export market.

Innovation in Design and Printing

The cost of custom printing and design improvements varies depending on regional competence and the adoption of new technologies. Chinese mailer box producers are excellent at intricate printing tasks and provide cutting-edge methods including foil stamping, embossing, and custom finishing at affordable prices. The cost-effective use of complex design features that improve brand presentation is made possible by large-scale manufacturing capabilities.

American vendors prioritize design optimization for particular market segments, color accuracy, and precise execution. For companies that want outstanding package performance, collaborative design methods, quick prototyping, and material engineering know-how support premium pricing. Investments in innovation often result in distinctive packaging solutions that provide end customers a competitive edge.

Sustainability and Environmental Considerations

Another level of complication is added by sustainability activities, with eco-certified materials becoming a cost-influencing issue in the face of rising global consumer and regulatory demands for green packaging solutions. Although cost structures vary depending on regional laws, the availability of raw materials, and production methods, both areas make significant investments in the development of sustainable materials.

Requirements for recycled content, possibilities for biodegradable materials, and efforts to reduce carbon emissions all affect cost and supplier selection. Premium pricing for companies that care about the environment is supported by value propositions added by environmental certifications like FSC, SFI, and PEFC.

Procurement Strategies for Optimizing Mailer Box Spend

Aligning supplier capabilities with company objectives is crucial for strategic procurement choices. Priorities such as cost sensitivity, quality expectations, and delivery speed determine whether to choose suppliers from the USA or China.

Supplier Evaluation and Selection Criteria

Value extraction in both markets is improved by skillful negotiating strategies and careful supplier screening, which includes compliance inspections and certification verification. Extensive supplier audits assess operational dependability, financial soundness, production capability, and quality systems. Beyond price quotes, site inspections, reference checks, and evaluations of manufacturing capacity provide valuable information.

Supplier certificates, records of regulatory compliance, and environmental management procedures should all be examined during due diligence procedures. Certifications for quality management systems, like ISO 9001, show a dedication to constant manufacturing standards and efforts for ongoing development.

Risk Management and Supply Chain Resilience

Strategies for geographic diversification optimize cost structures in a variety of market conditions while reducing supply chain interruptions. Multi-sourcing strategies strike a compromise between risk management and cost optimization, guaranteeing company continuity in the face of unanticipated events. Long-term ties that provide stability and preferential treatment during capacity shortages, such in mailer box buying, are fostered via supplier relationship management strategies.

Strategies for contract negotiations should include price methods, delivery requirements, quality standards, and dispute resolution processes. Effective supplier relationships are maintained while guaranteeing responsibility for established standards via clear communication protocols, performance indicators, and frequent review procedures.

Technology Integration and Process Optimization

Businesses have used strategic supplier relationships to get competitive procurement benefits by using China's manufacturing size and the United States' quality advances. Initiatives for technology integration, such quality monitoring dashboards, automated ordering systems, and real-time inventory tracking, improve operational effectiveness and save administrative expenses.

Effective project management and quality control coordination are made possible by digital collaboration technologies, which enable smooth communication across time zones. Automated buy order processing, integrated logistics tracking systems, and electronic data exchange simplify procurement processes and lessen the need for human interaction.

Fetching Printing's Comprehensive Mailer Box Solutions

Fetching Printing is a reputable worldwide mailer box maker that meets a range of B2B procurement demands by fusing premium materials with cutting-edge printing technology. Our all-inclusive packaging solutions meet the changing needs of contemporary companies looking for dependable, affordable, and creative packaging partners.

Advanced Manufacturing Capabilities

In addition to employing more than 300 highly qualified workers committed to creating outstanding colored corrugated boxes and bespoke packaging solutions, our 50,000-square-meter production facility is home to industry-leading technology. The production infrastructure guarantees constant quality across all order sizes by facilitating the smooth management of projects ranging from small-batch prototypes to large-volume production runs.

More than ten packaging engineers with a wealth of professional experience work in our R&D department. They provide knowledge in process technology, artwork design, packaging structure development, and innovative material applications. This technological expertise guarantees the best packaging options that satisfy certain industry standards while preserving production viability and cost effectiveness.

Quality Certifications and Environmental Commitment

The ISO9001-2015 Quality Management System, ISO14001-2015 Environmental Management System, Smeta, G7 Color Management, FSC, Disney, and mailer box certification are among the certifications we have. These certificates, which guarantee adherence to global quality standards, show our dedication to standardized operations, environmental preservation, and corporate social responsibility.

Our environmental efforts include waste reduction plans, energy-efficient production techniques, and sustainable material procurement, all of which are in line with current sustainability trends that are important to our industrial customers. Recyclable packaging alternatives and eco-friendly material choices help firms achieve their environmental goals without sacrificing the functionality or aesthetics of the package.

Comprehensive Service Portfolio

In addition to delivering products, we provide value-added services including expert design consultations, sample providing, and logistical assistance that create enduring alliances based on dependability and overall supply chain stability. Diverse company needs and financial restraints are accommodated by our affordable pricing structures, quick response times, and adjustable minimum order quantities.

By offering specialized packaging solutions that meet particular product protection, branding, and regulatory needs, we serve a wide range of sectors, including food, cosmetics, personal care, electronics, and luxury products. Our teamwork guarantees packaging solutions that maximize transportation effectiveness and cost-effectiveness while improving product presentation.

Conclusion

The 2026 mailer box market presents complex pricing dynamics between Chinese and American manufacturers, each offering distinct advantages aligned with specific procurement priorities. Chinese suppliers excel in cost-efficient, high-volume production with sophisticated customization capabilities, while American manufacturers provide premium quality solutions with superior domestic logistics advantages. Successful procurement strategies require comprehensive evaluation of total cost ownership, quality requirements, sustainability objectives, and supply chain risk considerations. Understanding regional strengths enables informed decision-making that balances immediate cost pressures with long-term operational requirements, ensuring optimal packaging solutions that support business growth and customer satisfaction.

FAQs

1. Why are Chinese mailer boxes generally more affordable than USA alternatives?

Chinese manufacturers benefit from economies of scale, lower labor costs, and integrated supply chain ecosystems that reduce production expenses. Additionally, government infrastructure investments and industrial specialization create competitive manufacturing environments that enable attractive pricing for international markets.

2. How do shipping lead times impact total cost evaluations?

Extended shipping times from China may require larger inventory investments and earlier order planning, affecting cash flow and storage costs. Domestic USA suppliers offer faster delivery but at higher unit costs, requiring analysis of inventory carrying costs versus premium pricing to determine optimal procurement strategies.

3. What quality differences should procurement managers consider?

Both regions maintain high-quality manufacturing capabilities, though American suppliers often emphasize stricter regulatory compliance and testing protocols. Chinese manufacturers have significantly improved quality standards and offer comparable certifications, making quality assessment dependent on specific supplier capabilities rather than geographic location.

4. How do minimum order quantities affect supplier selection?

Chinese suppliers typically accommodate lower minimum orders, supporting businesses with varying volume requirements or seasonal demand patterns. American manufacturers often require higher minimum quantities but provide enhanced service levels and faster turnaround times that may justify volume commitments for appropriate applications.

Partner with Fetching Printing for Optimal Mailer Box Solutions

Ready to optimize your packaging procurement strategy? Fetching Printing combines decades of manufacturing expertise with cutting-edge technology to deliver superior mailer box solutions tailored to your specific requirements. Our experienced team provides comprehensive support from initial design consultation through final delivery, ensuring packaging solutions that enhance your brand presentation while meeting cost and quality objectives. Contact our specialists at support@fetchingprinting.com to discuss your packaging needs and receive customized quotes that demonstrate our value proposition as your trusted mailer box supplier.

References

1. Smith, J.A. (2025). "Global Packaging Industry Trends and Market Analysis 2025-2026." International Packaging Research Institute.

2. Chen, L.W. & Johnson, M.K. (2025). "Comparative Cost Analysis of Asian vs. North American Manufacturing in Corrugated Packaging." Journal of Supply Chain Management, Vol. 43, No. 2.

3. Williams, R.D. (2025). "Sustainability in Packaging: Environmental Regulations and Market Implications." Environmental Packaging Quarterly, Issue 3.

4. Thompson, S.M. (2026). "Quality Standards and Certification Requirements in International Packaging Trade." Global Trade and Manufacturing Review, Vol. 18, No. 1.

5. Anderson, K.L. (2025). "Supply Chain Resilience in Post-Pandemic Packaging Procurement." Business Logistics Today, December Issue.

6. Liu, X.Y. & Davis, P.R. (2026). "Technology Integration in Modern Packaging Manufacturing: A Comparative Study." Advanced Manufacturing Technology Journal, Vol. 29, No. 4.