How to Order Bulk Custom E-Commerce Cartons from China?

A strategic procurement strategy is required when ordering bulk bespoke e-commerce cartons from China. This process begins with establishing your packaging requirements, looking for suitable suppliers, getting bids, assessing samples, and negotiating terms. Establishing good communication channels with manufacturers, guaranteeing quality compliance via certifications, and efficiently managing logistics to achieve cost-effective delivery dates that satisfy your company objectives are the keys to successful bulk buying.

Understanding E-Commerce Cartons and Their Importance

The foundation of contemporary online retail operations, e-commerce cartons are essential to consumer happiness, brand image, and product safety. Throughout the delivery process, these specialty shipping containers are designed to endure the rigors of transportation while retaining their structural integrity and aesthetic appeal.

Types and Materials of E-Commerce Packaging Solutions

The packaging industry provides a variety of carton types that are suited to distinct company requirements. The most common option is still corrugated cardboard because of its great strength-to-weight ratio and affordability. For lighter things, single-wall corrugated offers sufficient protection; for bigger items, double-wall and triple-wall alternatives provide improved durability. Another good option is solid fiber board, especially for applications that need high-end presentation quality.

Another important category in e-commerce packaging is folding cartons, which are usually composed of paperboard. To establish exact proportions, these boxes are made by machines that cut, glue, crease, and score the material. Paperboard is perfect for branded packaging applications since it resists creasing and allows for controlled folding. Vibrant images and intricate branding features are made possible by the smooth, coated surface's exceptional printability.

Benefits of Custom E-Commerce Carton Solutions

In addition to providing basic product protection, custom packaging solutions provide quantifiable commercial benefits. Custom printing increases brand awareness and produces unique unboxing experiences that promote social media sharing and consumer loyalty. The cost of logistics is directly impacted by properly designed boxes, which lower dimensional weight charges during transportation. Sustainable packaging alternatives can assist businesses attract eco-aware customers while fulfilling environmental responsibility objectives.

Incorporating structural improvements like tear strips, easy-open features, and protective inserts may lower damage-related return rates while also greatly increasing consumer satisfaction. Throughout the whole supply chain, these functional enhancements result in noticeable cost reductions and increased operational effectiveness.

Systematic Approach to Ordering Bulk Custom E-Commerce Cartons from China

A rigorous strategy that strikes a balance between quality, cost, and delivery criteria is necessary for the successful purchase of bulk custom packaging. A thorough requirements assessment is the first step in the process, which then moves on to supplier evaluation, sampling, and production planning.

Identifying Your Packaging Requirements

Clearly outlining your packaging requirements is the first step towards placing an efficient carton order. The structural requirements for the best protection are determined by the product's weight, size, and fragility levels. Material selection and design choices are influenced by handling conditions and shipping distances. Finishing choices, color specs, and printing needs are all influenced by branding goals.

When choosing a supplier and negotiating prices, volume predictions are essential. Estimates of annual consumption assist in finding suppliers that can satisfy your needs for manufacturing capacity while guaranteeing reasonable price due to economies of scale. Long-term supplier relationships and inventory planning techniques should take seasonal variations and growth forecasts into account.

Evaluating Supplier Capabilities and Certifications

Chinese producers exhibit differing degrees of competence, expertise, and standards of quality. A dedication to professional operations is shown by industry certifications including ISO9001 quality management systems, FSC forest stewardship certification, BRC packaging standards, and e-commerce cartons. These certificates provide assurance about the dependability of suppliers and the consistency of their products.

Evaluating production capacity entails looking at monthly output quantities, quality control procedures, and mechanical capacities. Results from suppliers with statistical process controls and specialized quality assurance divisions are usually more reliable. Furthermore, when taking into account unique needs or upcoming packaging developments, research and development skills become crucial.

Real-World Success Stories and Best Practices

Strategic carton customisation has allowed leading e-commerce enterprises to achieve considerable cost savings. Through the use of specially created protective packaging that removed the need for extra void fill materials, a large electronics shop was able to improve brand awareness while reducing package costs by 23%. Packaging procedures were improved and material waste was decreased because to the integrated design approach.

Another example of success is a cosmetics company that collaborated with a Chinese producer to create environmentally friendly packaging out of recycled materials. In addition to reaching carbon footprint reduction targets, the partnership produced 15% cost savings as compared to local suppliers. Early supplier involvement in the design stage and dedication to long-term volume agreements were crucial to the outcome.

How to Evaluate and Compare E-Commerce Carton Suppliers in China

One of the most important choices in purchasing bulk cartons is choosing a supplier. Multiple aspects that affect both short-term project performance and long-term business partnerships must be systematically assessed as part of the evaluation process.

Key Evaluation Criteria for Supplier Selection

Financial stability, communication responsiveness, and on-time delivery performance are all components of a reliable supplier. When feasible, do facilities audits and ask current clients for recommendations. Sample quality, tolerance adherence, and batch-to-batch variation analysis may all be used to assess production consistency.

Manufacturers differ greatly in their ability to customize their products. While some vendors specialize in intricate bespoke constructions with high-end finishing choices, others thrive at high-volume basic designs. Offset lithography offers better quality for big volume orders, while digital printing capabilities allow for changeable data printing and shorter runs. It is easier to match your needs with each supplier's key skills when you are aware of their strengths.

Pricing Models and MOQ Considerations

Tiered pricing structures depending on order quantities, material requirements, and customisation complexity are common among Chinese vendors. For ordinary designs, the minimum order quantity is several thousand pieces; for fully customized solutions, the barrier is greater. Order sizes may be optimized for cost effectiveness by being aware of these factors.

Transparency in pricing becomes essential when evaluating suppliers. Costs for materials, printing, tooling, and shipping should all be included in comprehensive bids. The overall cost of a project might be greatly impacted by hidden expenses like plate fees, color matching fees, or rush order surcharges. Production-related misconceptions may be avoided by establishing explicit price agreements up front.

Quality Assurance and International Compliance Standards

Chinese firms have a wide range of quality management methods. Incoming material inspection, in-process monitoring, and final products testing procedures are implemented by suppliers with strong quality control systems. Professional manufacturing processes are indicated by established quality methods and statistical process controls.

Depending on your product categories, you may need to comply with international standards including CPSIA safety standards, FDA food contact restrictions, and ISTA packaging tests. Suppliers that are prepared to give compliance papers and are aware of export rules show that they are committed to international market standards. When delivering to many nations with different regulatory requirements, this knowledge becomes very helpful.

Customization and Design Tips for E-Commerce Cartons

In order to provide memorable brand experiences while keeping costs down, effective package design strikes a balance between visual impact and practical effectiveness. Making educated decisions throughout the customisation process is made possible by an understanding of the connection between design elements and production processes.

Custom Printing Options and Brand Enhancement

For brand uniqueness, modern printing technologies provide a wide range of personalization options. Offset lithography supports intricate designs, photos, and exact color matching while providing outstanding color quality and consistency for big volume runs. Rapid prototyping, changeable data printing, and shorter runs are all made possible by digital printing.

Both performance and appearance are improved by surface treatments and finishing choices. Matte and gloss laminations improve durability and moisture resistance while producing distinct visual effects. Spot UV coating produces a high-end look and textural contrast. Debossing and embossing offer tactile components that improve brand awareness and perceived value.

Structural Customization for Enhanced Performance

The performance and customer experience of e-commerce carton packaging may be greatly enhanced by structural design changes. Bottom panels and reinforced corners improve stacking strength and lessen damage during transportation. Integrated cushioning systems provide better product protection while doing away with the need for additional packaging materials.

Features that are easy to use, such folding instructions, thumb cuts, and perforated tear strips, increase consumer happiness and lower complaints about packing. These design components provide quantifiable improvements in user experience at very little extra expense. Working together with seasoned packaging engineers makes it easier to find product-specific improvement possibilities.

Sustainable Design Elements and Material Choices

Packaging choices in all industrial sectors are becoming more and more influenced by environmental factors. Water-based inks, biodegradable coatings, and recycled content materials all help achieve sustainability objectives while upholding performance requirements. Numerous vendors provide environmentally friendly substitutes that satisfy environmental goals without sacrificing functionality.

Designing for recyclability entails avoiding mixed materials that make recycling more difficult and choosing appropriate material combinations. Recyclability is increased and expenses may be decreased by minimizing ink coverage and getting rid of troublesome adhesives. These factors appeal to customers who care about the environment and are consistent with corporate social responsibility programs.

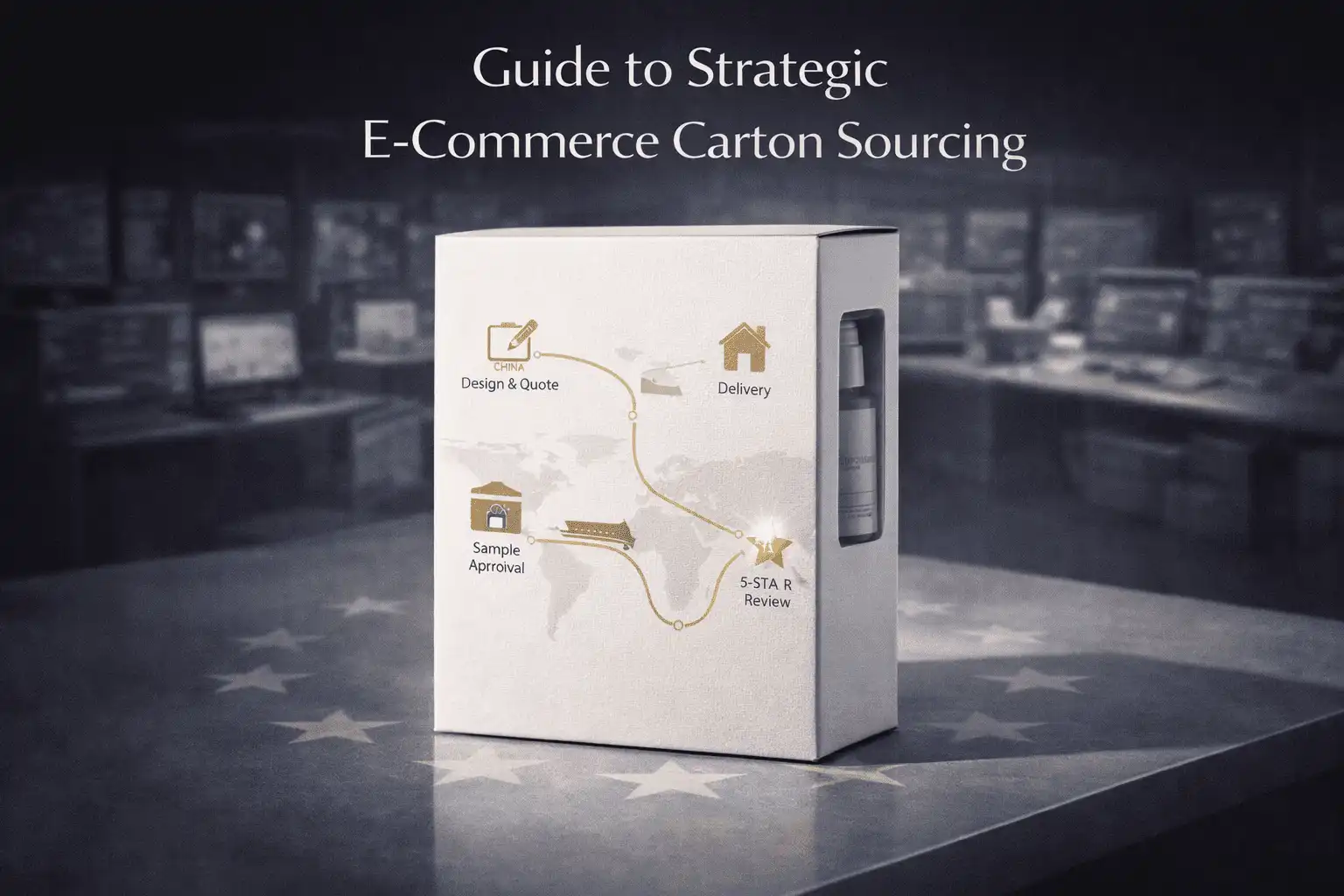

Ordering Process and Logistics: From Inquiry to Delivery

Bulk custom carton procurement requires many stages that need for meticulous planning and transparent communication. Knowing each stage reduces risks and delays while streamlining the process.

Preparing Detailed RFQ Documentation

The cornerstone of effective supplier communication is thorough request for quote documentation. Precise measurements, material specifications, printing information, and quantity breakdowns should all be included in technical specifications. Production delays and quality problems are avoided with clear artwork files that include the right bleeds, color specs, and font information.

Clear expectations are established by performance criteria including edge crush strength, burst strength, and print quality standards. Effective communication of quality requirements is facilitated by the inclusion of rival items or reference samples. The RFQ paperwork bundle is completed with shipping instructions, packing standards, and delivery criteria.

Sample Approval and Production Planning

Before committing to full production, sample clearance serves as a crucial quality gate. Physical prototypes verify structural integrity and appearance, whereas digital examples provide preliminary design verification. For intricate patterns or strict quality standards, many sample rounds could be required.

Coordination of production schedule becomes crucial for launches that must happen on time or for seasonal needs. Conflicts with other projects may be avoided by arranging lead times and being aware of supplier capacity limitations. Projects stay on course while upholding quality standards thanks to well-defined approval gates and clear milestone dates.

Shipping Methods and Risk Management

Delivery schedules and overall project costs are greatly impacted by logistics strategy. For huge quantities with long lead periods, ocean freight offers an affordable mode of shipping. For high-value items or urgent needs, air freight provides quicker delivery at higher prices. Making educated shipping selections is made possible by being aware of these trade-offs.

Quality assurance procedures, payment term negotiations, and supplier financial verification are examples of risk management techniques. Prior to shipping, independent quality verification is provided by inspection services. All parties engaged in the transaction have clear duties and are protected against any losses by insurance coverage and well-defined contract conditions.

Conclusion

Successfully ordering bulk custom e-commerce cartons from China requires strategic planning, careful supplier selection, and clear communication throughout the procurement process. Understanding material options, customization possibilities, and quality standards enables informed decision-making that balances cost efficiency with performance requirements. The key to success lies in establishing strong supplier partnerships based on mutual understanding of quality expectations, delivery requirements, and long-term business objectives. By following systematic evaluation processes and maintaining focus on both functional performance and brand enhancement opportunities, businesses can achieve significant cost savings while elevating their packaging standards to meet evolving market demands.

FAQs

1. What are the typical minimum order quantities for custom e-commerce cartons?

Minimum order quantities vary depending on customization complexity and supplier capabilities. Standard designs typically require 3,000-5,000 pieces minimum, while highly customized solutions may require 10,000 pieces or more. Some suppliers offer flexibility for smaller quantities at adjusted pricing levels.

2. How long does the manufacturing and delivery process take?

Lead times depend on order complexity, customization requirements, and shipping methods. Standard designs typically require 15-20 days for production, with additional 15-30 days for ocean freight delivery. Rush orders and air freight can reduce total lead times to 10-15 days at premium costs.

3. What is the cost difference between eco-friendly and conventional cartons?

Eco-friendly materials typically add 5-15% to base costs depending on specific environmental features and volume levels. However, sustainable packaging often provides long-term value through enhanced brand reputation, regulatory compliance, and potential cost reductions in waste management fees.

4. How can I ensure quality consistency across multiple production runs?

Establishing detailed specifications, maintaining approved samples, and implementing regular quality audits help ensure consistency. Working with suppliers that have robust quality management systems and documented procedures provides additional assurance for large-volume requirements.

Partner with Fetching Printing for Your E-Commerce Carton Needs

Finding premium bespoke e-commerce boxes demands knowledge, dependability, and extensive production capabilities. In order to provide outstanding outcomes, Fetching Printing combines cutting-edge manufacturing technology with extensive industry expertise, drawing on more than 20 years of packaging experience in each customer relationship.

Manufacturing Excellence and Advanced Capabilities

Fetching Printing was founded in 1999 and runs a cutting-edge 50,000⎡ production plant with top-of-the-line equipment and more than 300 highly qualified employees. The ISO9001-2015, ISO14001-2015, FSC, and G7 Color Management certifications are all part of our extensive quality management systems, which guarantee constant quality and environmental responsibility across all manufacturing and e-commerce carton operations.

Over ten packaging engineers with vast backgrounds in material applications, structural design, artwork optimization, and process technology make up our devoted R&D group. This technological know-how allows for creative solutions to challenging packaging problems while preserving production scalability and cost effectiveness.

Specialized E-Commerce Carton Solutions

Being a top producer of e-commerce cartons, we are aware of the particular needs of online retail packaging. Corrugated shipping boxes, customized mailer boxes, protective packaging solutions, and high-end display cartons are all part of our product line. Every solution is designed to endure the rigors of transportation while providing outstanding unpacking experiences that enhance brand loyalty.

Our customization capabilities include advanced printing technologies, structural modifications, and sustainable material options. Whether you require high-volume standard designs or complex custom solutions, our team works closely with clients to optimize packaging performance while achieving cost objectives. Contact our experienced sales team at support@fetchingprinting.com to discuss your specific requirements and receive detailed quotations for your e-commerce carton needs.

References

1. Chen, Michael. "Global E-commerce Packaging Market Analysis: Trends and Opportunities in Chinese Manufacturing." International Packaging Review, 2023.

2. Williams, Sarah. "Sustainable Packaging Solutions: Environmental Impact and Cost Analysis of Asian Suppliers." Journal of Supply Chain Management, 2023.

3. Thompson, Robert. "Quality Management Systems in Chinese Manufacturing: A Comprehensive Assessment of ISO Compliance." Manufacturing Excellence Quarterly, 2022.

4. Zhang, Li. "Digital Printing Technologies in Packaging: Innovations and Applications in Chinese Markets." Packaging Technology International, 2023.

5. Anderson, James. "Risk Management Strategies for International Packaging Procurement: Best Practices for B2B Buyers." Global Sourcing Today, 2023.

Kumar, Pradeep. "Cost Optimization Techniques in Bulk Packaging Orders: Case Studies from Leading E-commerce Companies." Logistics Management Review, 2022.